Phase Shift Focus Monitor

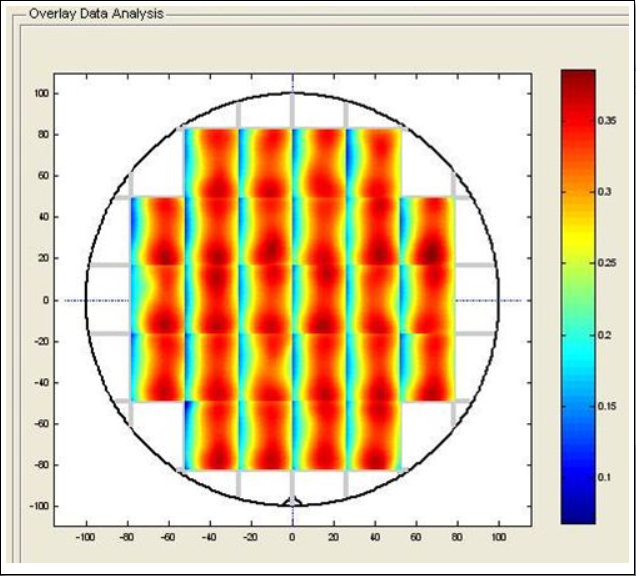

With over 750 users worldwide, Benchmark Technologies’ Phase Shift Focus Monitor (PSFM) Test Reticle is the standard by which lithographers evaluate scanner and stepper focus and lens performance. Using patented technology, the PSFM pattern is comprised of a traditional box-in box structure that can be easily measured on industry standard overlay tools common to most wafer fabrication facilities. The phase-shifting of this pattern cause the inner box to become displaced vs. the outer box in a defocus condition. The use of PFSM allows focus to be monitored with a resist-based method using a single wafer lot thus saving hours of precious lithography tool time that would be consumed by traditional OEM methods.

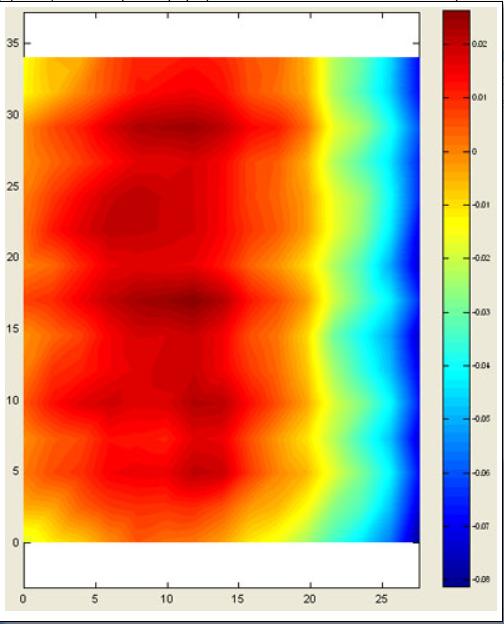

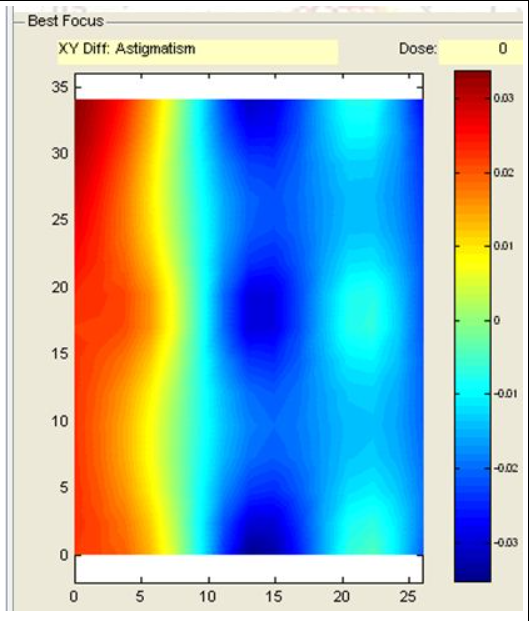

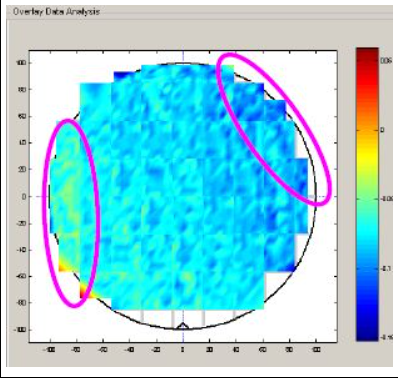

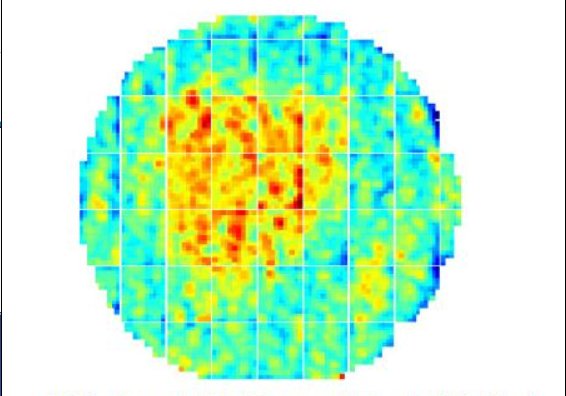

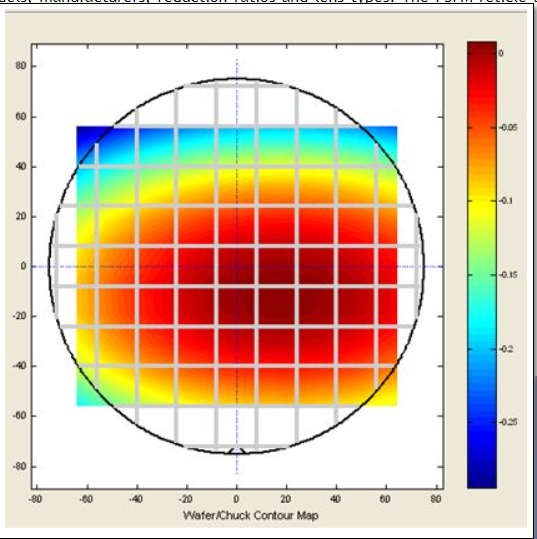

PSFM can also be used as an engineering tool to troubleshoot focus problems. By analyzing the target displacement using our PSFM Data! software, engineers can develop a thorough understanding of the z-axis conditions of their lithography system and can extract lens, chuck and topographic contributions to focus. Numerous technical studies have been published by many leading industry researchers showing the power of the PSFM as an analysis tool. A sampling of these papers can be provided upon request through our Contact Us page

PSFM Advantages

Use of the Focus Monitor Reticle method provides several advantages over other techniques. The PSFM reticle provides data over many points within a single field. A real-time snapshot of focus is gathered. The PSFM is compatible with all widely used overlay measurement tools, thus allowing automated collection of focus data. Operator interpretation is eliminated, thus increasing repeatability of the data, and reducing the time required for evaluation and characterization.

- Enhances lithography-tool performance

- Improves overall throughput by reducing lithography tool downtime for focus-related preventative maintenance

- Evaluates and compares new and installed lithography tools using a common method

Have questions? See our PSFM FAQ.